Scope of supply includes machine and control panel as specified above. Customer will have to provide for Foundation and civil work as required. Electrical connection up to panel. 2T Electric hoist for Loading / Unloading of mould and product. Diesel Storage tank is your scope. Machine is supplied with Diesel burner. Biomass burner is optional or in your scope. We recommend 2,00,000 Kcal Biomass burner for PS 1000/2 and 3,00,000 Kcal Biomass burner for higher models. Installation of Biomass burner is also not in our scope.

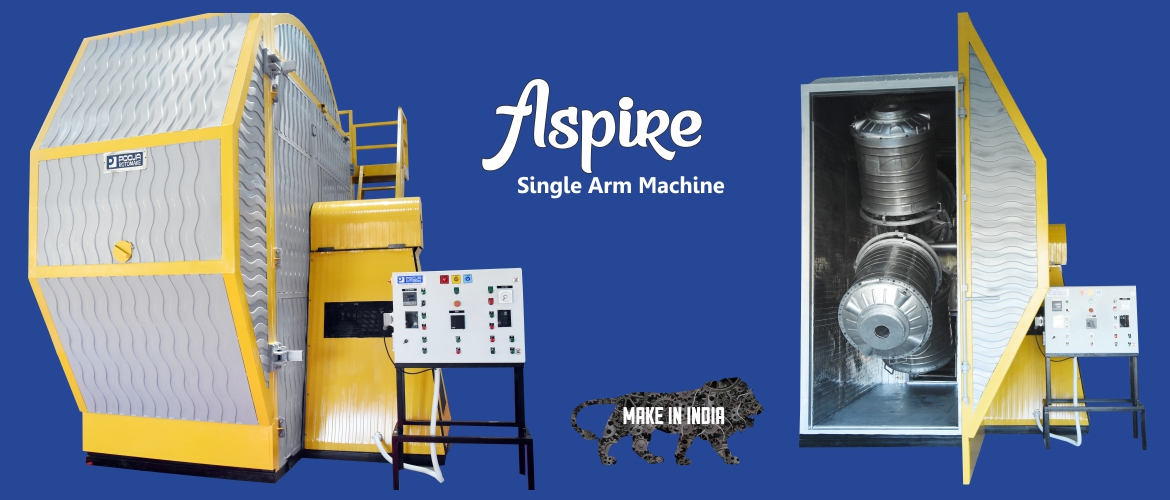

Aspire-2000-2

Operating Parameters of Aspire-2000-2

| Sr. No. | Machine Description | Specifications |

|---|---|---|

| 1 | Mould on straight arm | 2000 Ltr. x 2. 1500 Ltr. x 2. 1000 Ltr. x 4 |

| 2 | Total Cycle Time | 75 min. for Double Layer |

| 3 | Production Per Day | 60,000 Ltr.. Max (24 hrs). |

| 4 | Production Capacity | 60 tanks/day for 1000 Ltr. 30 tanks/day for 2000 Ltr. & 1500 Ltr. |

| 5 | Electrical Load | 10 HP (415 Volt 3 phase). |

| 6 | Diesel Consumption ***LPG Consumption ***Biomass Consumption |

10 Ltr. / Cycle 8 Kg / Cycle 24 kg / Cycle |

| 7 | Process Temperature | 180- 220 Degree. |

| 8 | Space for Machine | L 9 Mtr x W 7 Mtr x H 6 Mtr. |

| 9 | Machine suitable for | DL, TL FL or Foam Layer |

| 10 | Manpower | 2 Semi skilled persons per shift. |

***Machine supplied with Diesel burner other burners are optional

Technical Specifications of Aspire-2000-2

| Machine Description | Specifications |

|---|---|

| Spindles | 1 |

| Maximum Weight on Straight Arm | 600 Kg |

| Spider Diameter | 1600 mm |

| Max Mould Diameter | 1400 mm |

| Max Mould Height | 1570 mm |

| Major Axis R.P.M | 0-6 |

| Minor Axis R.P. | 0-6 |

| Max Temperature ˚C | 250.0 |

| Circulating Blower C.F | 18000 |

| Electrical Supply Voltage | 415 V, 50 Hz 3 Phase & Neutral |

| Blower Motor | 5 HP 415 V 1440 RPM Crompton |

| Major Motor | 3 HP 415V 1440 RPM Crompton |

| Minor Motor | 2 HP 415V 1440 RPM Crompton |

| Burner Motor Riello |

0.25 230 Volt 1440 RPM make |

| Major Gear Box | Size 50 Ratio 70:1 Make Panchal |

| Minor Gear box | Size 40 Ratio 40:1 Make Panchal |

| Bearings | All ZKL Make |

| Blower Impeller | 450 mm Double blades |

| Major Shaft | OD 150 mm ID 60 m |

| Minor shaft | OD 50 mm Solid |

| Furnace Inside sheet | 0.40 mm SS polish sheet |

| Furnace Outside sheet | 1.2 mm CRC Sheet |

| Insulation | Mineral wool |

| Spider for 1000 Ltr. mould | 1250 mm |

| Spider for 2000/ 1500 Ltr. Mould | 1600 mm |

SCOPE OF OUR SUPPLY

ERECTION AND COMMISSIONING

Erection and commissioning are free of cost You will arrange to and fro, lodging and food for our team. You will also arrange necessary unskilled person, Crane or Chain pully block, necessary tools, Raw material and fuel for trail. Our team will train your operator for Process, Trouble shooting and Maintenance of Machines. Our team will stay at your place for Max 5 days.