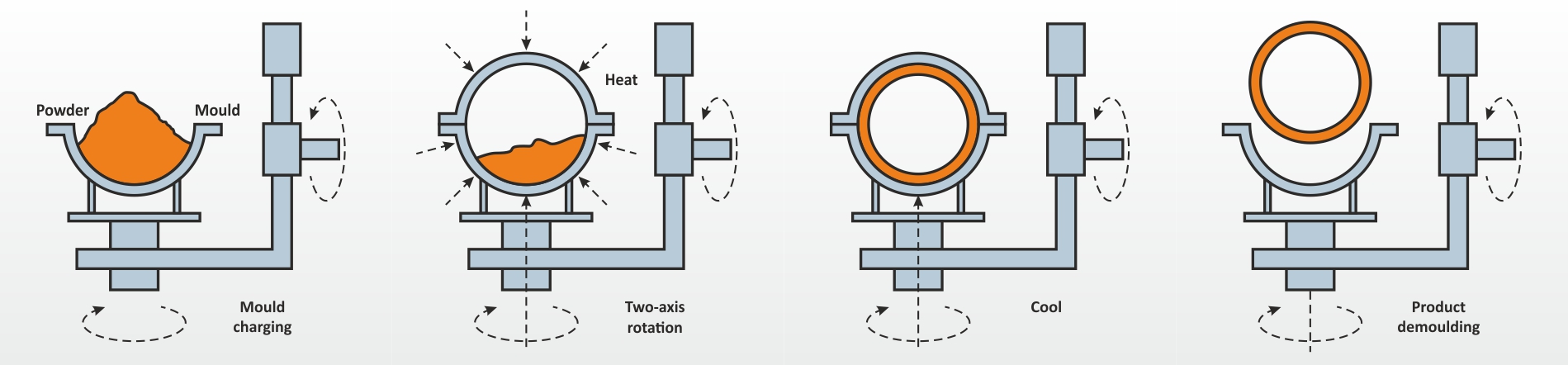

Rotational moulding, also known as roto casting or roto moulding, is a low pressure, high temperature manufacturing method for producing hollow, one-piece plastic parts. As with most manufacturing methods for plastic parts, rotational moulding evolved from other technologies. Currently rotational moulding is a very competitive alternative to Fiberglass, thermoforming and injection moulding for the manufacture of hollow plastic products. This is because it offers designers the opportunity to achieve the economic production of stress-free articles, with uniform wall thickness and potentially complex shapes

Overview of Rotational Moulding

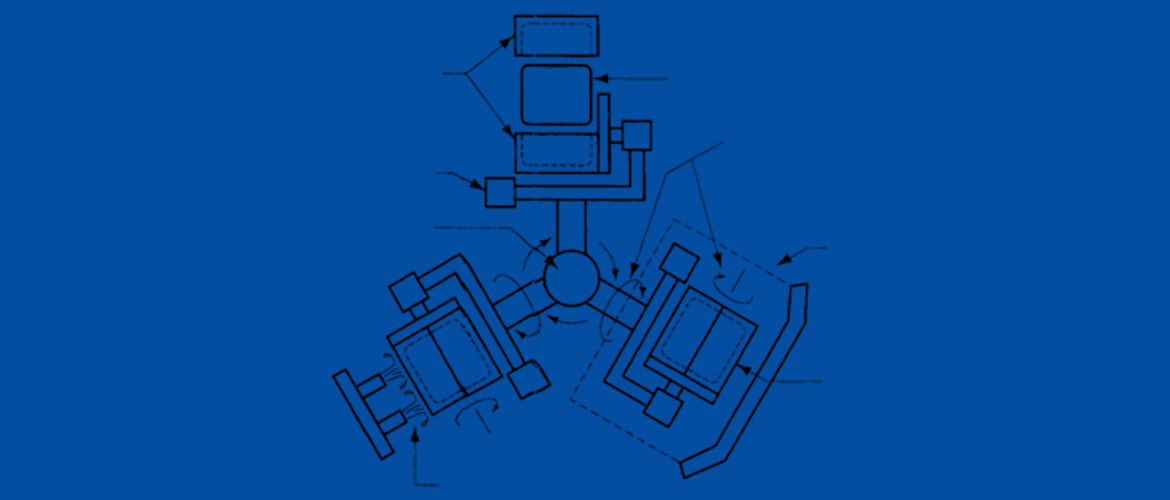

Modern rotational moulding is characterized as being an atmospheric pressure process that begins with fine powder and produces nearly stress-free parts. It is an essential requirement that the plastic withstands elevated temperatures for relatively long times. As no pressure is used in forming the plastic, rotational moulds usually have thin walls and can be relatively inexpensive to fabricate. For simple parts, mould delivery times can be days or weeks. Modern, multi-armed machines allow multiple moulds of different size and shape to be run at the same time. With proper mould design, complex parts that are difficult or impossible to mould any other way, can be rotationally moulded. With proper mould design and correct process control, the wall thickness of rotationally moulded parts is quite uniform, unlike structural blow moulding or twin-sheet thermoforming. And unlike these competitive processes, rotational moulding has no seams or weld lines.

SPECIAL Nature of Rotational Moulding

Rotational moulding is a unique manufacturing method in that the plastic starts at room temperature and it is placed in a mould that is also at approximately room temperature. The whole assembly is then heated up to the melting temperature for the plastic, and subsequently it must be cooled back to room temperature. When the mould rotates in the oven, its metal wall becomes hot, and the surface of the powder particles becomes tacky. The particles stick to the mould wall and to each other, thus building up a loose powdery mass against the mould wall.