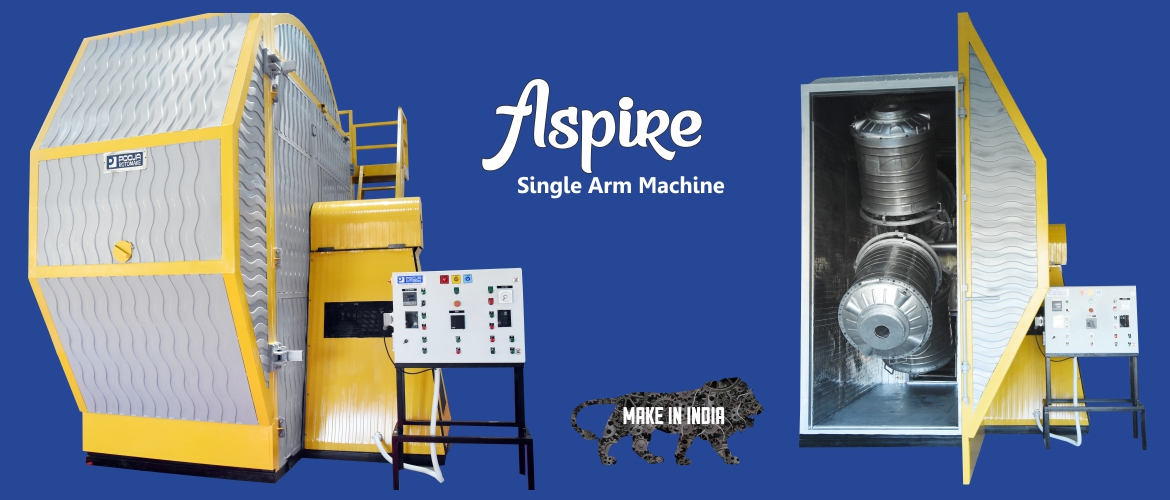

Aspire Series machines are the Latest version of World Class Rotational Moulding machines which suits the requirement of customer worldwide. Pooja Roto make’s Single arm machines series is latest and most modified version of Single arm machines available market. Which gives more comfortable production and quality. Machine is easier to operate and almost maintenance free.

Available Models in Single Arm Series

1. Aspire – 1000 x 2 Suitable for - 1000 Ltr.. x 2, 500 Ltr.. x 4, 750 Ltr.. x 2, 300 Ltr.. x 4

2. Aspire – 2000 x 2 Suitable for - 2000 Ltr.. x 2, 1500 Ltr.. x 2 ,1000 Ltr.. x 4, 750 Ltr.. x 4

3. Aspire - 5000 Suitable for - 5000 Ltr.. x 1, 3000 Ltr.. x 1, 2000 Ltr.. x 1, 1500 Ltr.. x 1

Model Aspire 1000/2 Machine is suitable for 1000 Ltr.. x 2 tanks at a time or 500 Ltr.. x 4 tanks or 750 Ltr.. x 2 or 300 Ltr.. x 4 tanks at a time. Machine is also suitable for Double layer, Triple layer or Foam layer tanks. Market contributes 80% of sale tanks which are below 1000 Ltr.. therefore Model Aspire 1000/2 meets the demand of market to a large extend. Model Aspire 1000/2 is a Base Machine therefore everybody should start with Model Aspire 1000/2 and then think about higher versions. Aspire Series of Machines are equipped with Excellent process control which gives more precise quality which today’s market demands.

◆ High Productivity

◆ Fuel Efficiency

◆ Low Electric Power requirement

◆ Suitable for Double Layer, Triple Layer, Four Layer or Foam Layer

◆ High and Fast returns on investment

◆ Low Maintenance Cost

Aspire Series of Machines Have Following Feature

Furnace :

The furnace is constructed by using ERW hallow square & rectangular sections; inner structure of furnace is constructed by using stainless steel sheet. To reduce heat losses an insulation of 80 mm is used.

The oven is very compact and hence fuel efficient. For multilayer tanks top loading system is provided with ladder. For better appearance and long life the oven is painted with Polyurethane paint.

Diesel Burner:

Italian “REILLO” make burner, which is suitable for diesel is used. The burner is most fuel efficient with low noise and smoke free firing. For higher efficiency and low maintenance, a two stage 10-micron filter is used. It has flame failure indication along with safety feature which meets International safety standards.

Biomass Burner :

Now a days Diesel burner are replacing all over places with Biomass burners. Solid Biomass burner uses agro waste Pallets as a fuel. Which reduce fuel cost to extend of almost 30-40 %. This saving on fuel cost add great value to production cost reduction.

Solid waste Fuel Normally called as Pallets are now easily available and burner function is user friendly.

Re-Circulating Blower :

Aspire series machines blower impeller is made of stainless steel and is dynamical balanced. It is a high capacity, low R.P.M and low noise blower. The blower shaft is supported on both sides with maintenance free high-quality bearing.

Straight Arm :

Heavy duty straight Arm with One side mounting is use instead of St arm with Two side mounting. Which is mounted on One side of Furnace with

heavy duty Two Bearing Housing. Motor and Gear box are on same side of furnace. Mould rotates in both X and Y directions with 6 R.P.M max.

Variable speed A.C drive duty motors are provided. Heavy duty gear box is used for smooth operation. Chain drive is used for low maintenance. Mould mounting is very easy & fast.

Control Panel :

A user-friendly control panel is provided. Schneider make drives are used for controlling speed of major and minor axis motor. For getting uniform thickness speed of drive can be vary on line with High speed and Low Speed buttons. Voltage display for three phase and indicator lamAspire for voltages. Digital temperature controller, Cycle timer are provided for easy operation & control. Hooter, flame failure lamp, safety interlocks are provided for safety propose.

Ladder and Platform :

Ladder and Platform is provided for Multilayer tank production is provide